Liberty Clark, Inc. specializes in contract pad printing services for medical device OEM and OEM suppliers in the Minneapolis metro and throughout the country. We offer certified class 7 cleanroom printing operations.

High Precision Pad Printing Services

Liberty Clark, Inc. provides high-quality precision pad printing services for the industrial and medical device and diagnostics markets. The core of our business is focused on medical device pad printing.

Medical device standards are extremely high. Precision, repeatability, and documentation is key. Certified ISO 9001:2015, Liberty Clark is committed to continual process improvement. Our 20 plus years of expertise and state of the art equipment is uniquely suited to meet specifications for all types of industrial and medical devices.

Furthermore, our pre-treatment and post-treatment process dramatically improves adhesion on substrates such as PP, Nylon, PC, Acetal, and Silicone. Our equipment also allows us to print on irregular shaped surfaces for products such as catheters, syringes, and hypo tubes.

Class 7 Cleanroom

Our certified Class 7 cleanroom is a special-use room reserved for pad printing jobs which require a very low particle count environment.

Before starting a pad printing job for medical devices, we filter all the air out of the Class 7 clean room to remove contaminants. Throughout the pad printing process, air is continuously recirculated through High-Efficiency Particulate Air (HEPA) filters.

Benefits of Pad Printing

Pad printing is a gravure-printing process that makes it possible to transfer a 2-d image onto 3-d objects.

Unlike other printing processes, pad printing has the ability to print on nearly any shape or surface including concave, convex, curved, uneven and hollows. For medical devices, this means accuracy and precision on devices such as syringes.

Pad printing is also capable of printing on almost any material including plastic, metal, glass, ceramics and even food.

Lastly, pad printing offers better resolution than other printing processes. Resolution is key for printing on medical devices for obvious reasons.

Contact Us

Pad Printing Applications on Medical Devices

There are a number of applications for pad printing on medical devices.

Below is a list of some of the applications we at Liberty Clark, Inc. have been involved with along with some images of completed projects…

Automated External Defibrillator (AED)

Disposable Suture Device and Components

EBUS-TBNA Needle Outer Handle

Pacemaker Can Demo

Pacemaker Header Demo

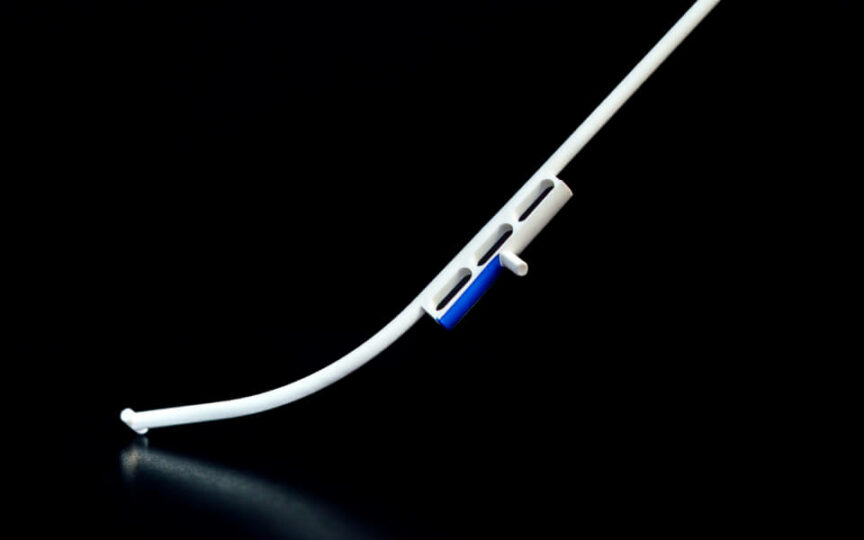

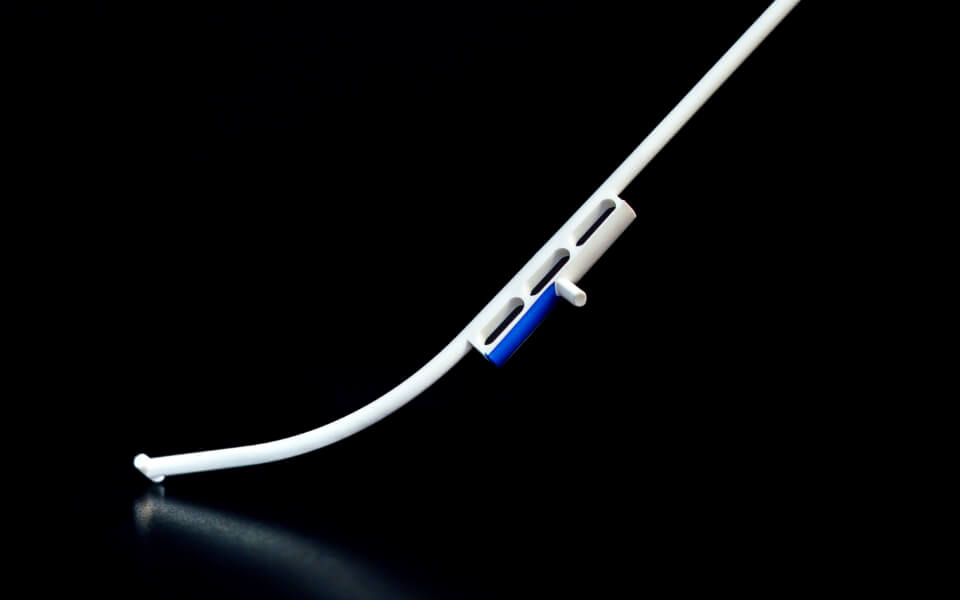

Infusion Tubing Guide

Medical Device Assembly

Medical Device Enclosure

Medical Device Face Plate

Medical Device Housing

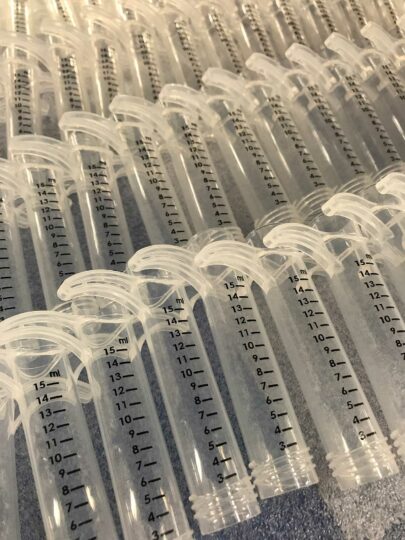

Polycarbonate Syringe Body

Polypropylene Syringe Barrel

Respirator Helmet Components

And More

Pad Printing Challenges

Quality images and precise tolerances are required in the medical industry, which means choosing the right ink sytem and pad for your project is crucial. Choosing the wrong ink or pad can result in wasted time delaying your medical device from entering the marketplace.

With over 20 years of experience pad printing on medical devices, we have documented a long list of substrates and compatible medical grade ink systems.

Our pad printing experts can help you determine what options are available for your project based on the application and substrate of the device. Fill out our online form and our pad printing experts will help you navigate your options via email.

Medical Syringe Barrel Pad Printing

Liberty Clark, Inc. specializes in precision medical syringe pad printing, ensuring top-quality and long-lasting markings on various syringe types. With over 20 years of experience, our ISO 9001:2015 certified processes greatly improve medical device and syringe quality assurance. Our advanced Class 7 cleanroom and specialized pre-treatment and post-treatment methods enhance ink adhesion on materials like Polypropylene and Polycarbonate. We offer customized solutions to meet the unique requirements of each syringe product, ensuring clear, accurate, and reliable print quality.

Regulations for Medical Pad Printing

The medical industry, in general, is very regulated because we are dealing with a number of factors that directly impact the health of a person.

At Liberty Clark, Inc., we are certified ISO 9001:2015. We are committed to consistently provide products and services that meet customer and regulatory requirements and have the documentation to back it up.

Experienced Medical Device Pad Printing Professionals

Liberty Clark, Inc. are your experienced professionals for your next medical device pad printing job. We will communicate with you every step of the way to ensure the job is done right the first time and is done on time!

Medical Device Pad Printing FAQ’s

60% of all of our business is directly related to pad printing services for medical devices.

We have been providing our services to the medical device industry for over 10 years.

Liberty Clark, Inc has the capabilities to handle pad printing jobs of any size. Whether you have a few thousand medical or tens of thousands of medical devices that need pad printing, we have the equipment and expertise to handle the job.

Liberty Clark, Inc regularly completes multiple pad printing jobs that require more than 40,000 units printed per month.

Depends on the volume and number of setups to complete the artwork requirements. Generally, 1 day to 3-weeks.

Yes. All Medical Grade ink systems we use are Class VI and sourced only through major manufacturers.

We have the ability to color match and mix all PMS colors in-house.

Yes. We offer in-house corona pretreatment process services.

A Dyne pen will help determine the surface tension of a given substrate. Most ink systems will require a surface tension of at least 42 Dyne. We can perform this test for you.

Yes! It is very wise to consider the artwork requirements of the device before the technical drawing is approved. We are here to help.

Yes. If requested.

Liberty Clark is certified ISO 9001:2015